| Category: CO2 Production & CO2 Recovery Plant > Central Control Systems > |

PLC Control Systems

The Wittemann PLC control systems are designed to provide the best control solution for the CO2 plant. Based on various systems and customer requirements, Wittemann control systems are available in a wide range of functional design, and can be connected in a wide variety of networks for distributed processing and distributed I/O. Wittemann will provide the customer a wide range of the PLC processor in memory, I/O capacity, instruction set, and communication to meet your exact application requirements.

PLC Processor Overview: Allen-Bradley, MicroLogix 1000 family; MicroLogix 1200 family; MicroLogix 1500 family; SLC 5/01; SLC 5/02; SLC 5/03; SLC 5/04; SLC 5/05; PLC 5 family. Siemens, SIMATIC S7-200 Micro PLC; SIMATIC S7-300 Modular mini PLC; SIMATIC S7-400 Power PLC, Omron PLC's, CQM1; C200H; CPM1…

Network: To have flexibility of communication network capability, our control network has a wide range of network selection: TCP/IP Ethernet, DeviceNet Network, Data Highway Plus Network, ControlNet Network, Remote I/O Network, DH-485 Network, Profibus Network… Typical devices communicating across the network include: host computer servers, PCs, PLC's, HMIs, Data acquisition devices, DCS.

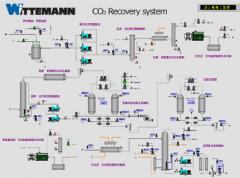

Operator interface terminals provide the capability in space-saving, flat-panel designs and feature in pixel graphics, high-performance functionality in color, grayscale and monochrome flat-panel display. For a large system, The PC based HMI system is available and enables engineers, supervisors, managers and operators to view and control the entire system through graphical representations of their production processes. The central control and visualization system provide real-time graphics display, collect and analyze historical data, view real-time plant floor data, track and improve production.

Key Features

- Wide selection from a compact system to a large system.

- Expandable.

- Network flexibility.

- Open communication architecture offers routable connectivity between plant-floor devices, central control system and business computing system.

- Remote control and monitoring.

- Redundant system.

- Simple and affordable processors.

- Wire reduction.

- Diagnostics provide predictive failure warning and troubleshooting to help operator to reduce downtime.

- Flexibility to add or move the device and cable segments.

- Quick installations and start-up.

-

Automatic control, easy to operate, monitor and maintenance.